MIL-PRF-38039D

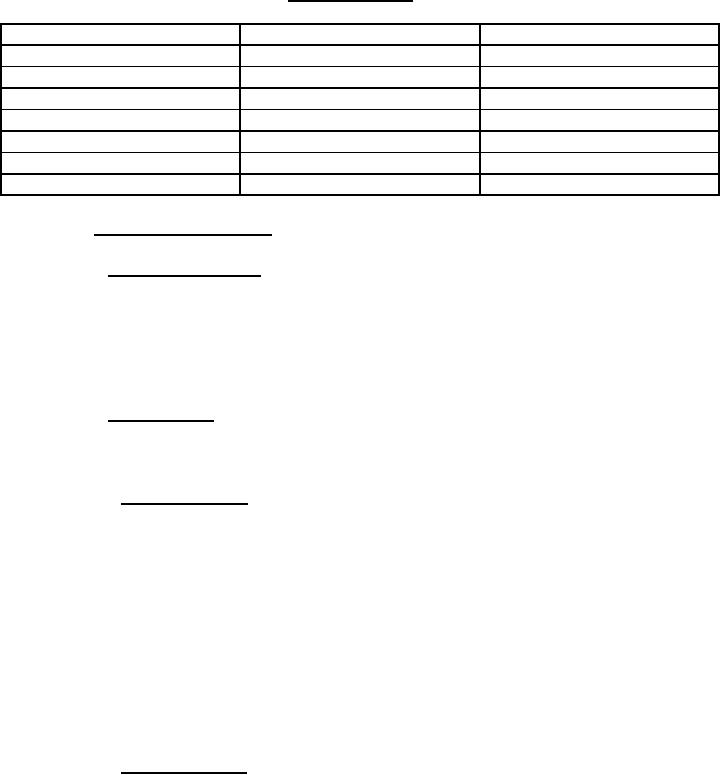

TABLE II. Testing sequence - (Continued).

4.5.7.8

13

4.5.7.9

4

4

4.5.7.10

16

4.5.7.11

17

4.5.7.12

18

4.5.7.13

21

4.5.8

19

4.5.9

20

4.3 Conformance inspection. This inspection shall include the tests in 4.3.1 and 4.3.2.

4.3.1 Individual inspection. The system shall be subjected to the following tests. Unless

otherwise specified in the test description, all visual observations of performance shall be made

at a distance of approximately two feet.

a. Examination of product (see 4.5.1)

b. Input circuit response (see 4.5.2)

4.3.2 Sampling tests. Sampling shall be performed on two groups of systems, and shall

include the tests indicated below. Sampling shall follow the guidance contained in ASQC-Z1.4 at

an initial inspection level of normal.

4.3.2.1 Group A samples. Group A samples shall be subjected to the following tests.

The mounting of light assemblies, controls, and electrical components shall simulate the

mounting required for the finished system. If required by the procuring activity, the illumination

test facility to be employed for illumination tests shall be approved prior to testing (see 6.2).

a.

Individual tests (see 4.3.1)

b.

Power consumption (see 4.5.4)

c.

Acceleration test (see 4.5.7.9)

d.

Low temperature test (see 4.5.7.1)

e.

High temperature test (see 4.5.7.2)

f.

Vibration test (see 4.5.7.3)

g.

Lighting (see 4.5.6)

4.3.2.2 Group B samples. Group B samples shall be selected and subjected to the

following tests.

a.

Group A sample tests (see 4.3.2.1)

b.

Shock test (see 4.5.7.4)

c.

Humidity test (see 4.5.7.5)

d.

Fungus test (see 4.5.7.6)

e.

Salt fog test (see 4.5.7.7)

f.

Dust test (see 4.5.7.8)

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business