MIL-DTL-9320E

4.3.1 Test samples. The qualification test samples shall consist of five signals

representative of the production equipment. The samples shall be identified with the

manufacturer's part number and any additional information required by the procuring activity.

4.3.2 Test report. After completion of the qualification tests, the contractor shall prepare

a test report summarizing the test results. The contractor may refer to MIL-HDBK-831 for

guidance in preparing the test report.

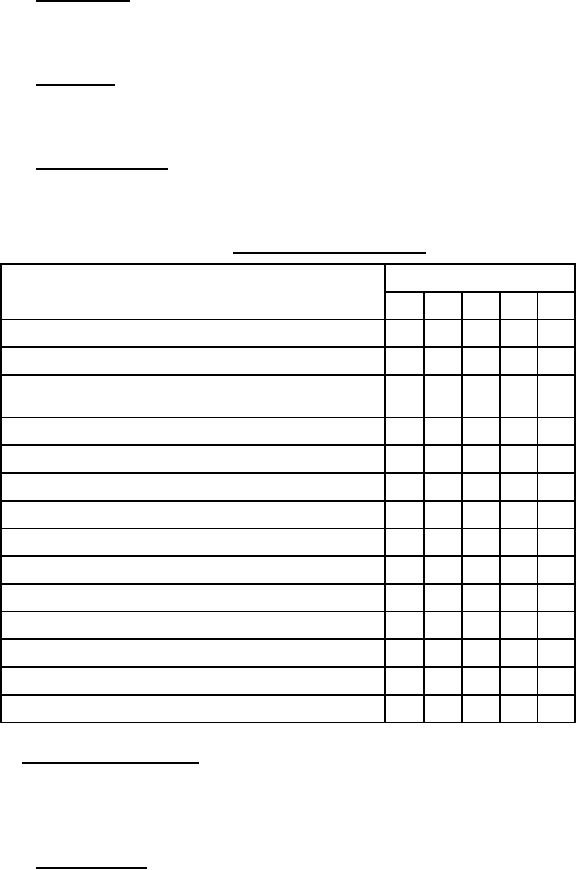

4.3.3 Qualification tests. Qualification tests shall consist of all the tests specified in 4.5. At

the conclusion of each environmental test, the signal shall be tested for operation and audio output.

The tests shall be performed on the samples as indicated and in the order listed in table II.

TABLE II. Qualification test schedule.

Sample number

1

2

3

4

5

Test

Individual tests (see 4.4.1)

X

X

X

X

X

Internal impedance (see 4.5.5)

X

X

X

X

X

Audio and flashing lamp output circuits (see

X

X

X

X

X

4.5.6)

Frequency and interruption rate (see 4.5.7)

X

X

X

X

X

Reliability (see 4.5.8)

X

X

Vibration (see 4.5.9)

X

Shock (see 4.5.10)

X

High altitude-low temperature (see 4.5.11)

X

Pressurization (see 4.5.17)

X

X

High temperature (see 4.5.13)

X

Low temperature (see 4.5.14)

X

Short circuit (see 4.5.15)

X

X

Harmonic content (see 4.5.16)

X

X

X

X

X

Hermetic seal (see 4.5.12)

X

X

4.4 Conformance inspection. Conformance inspection shall consist of:

a. Individual tests (see 4.4.1).

b. Sampling tests (see 4.4.2).

4.4.1 Individual tests. Each signal shall be subjected to the following tests as described

in 4.5:

a. Examination of product (see 4.5.1).

b. Dielectric strength (see 4.5.2).

c. Current consumption (see 4.5.3).

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business